Pre-engineered and prefabricated buildings ordering guide

Purpose

The purpose of this page is to create a comprehensive ordering guide that assists ordering agencies, particularly contracting officers, to effectively use the Multiple Award Schedule to purchase total solutions for pre-engineered/prefabricated buildings. This ordering guide is not a stand-alone reference — it is recommended that you also become familiar with the MAS Desk Reference Guide and Federal Acquisition Regulation 8.4 Federal Supply Schedules. This Ordering Guide may be revised from time to time.

What are pre-engineered/prefabricated buildings?

The most widely used form of prefabrication in building and civil engineering is the use of prefabricated concrete and prefabricated steel sections in structures where a particular part or form is repeated many times. Modular Construction can be considered a form of Prefabricated Construction.

Precast is a construction product (mostly concrete) produced by casting concrete in a reusable mold or “form” which is then cured in a controlled environment, transported to the construction site and lifted into place. In contrast, standard concrete is poured into site-specific forms and cured on site.

Prefabrication is the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be located. The term is used to distinguish this process from the more conventional construction practice of transporting the basic materials to the construction site where all assembly is carried out.

The term prefabrication also applies to the manufacturing of things other than structures at a fixed site. It is frequently used when fabrication of a section of a machine or any movable structure is shifted from the main manufacturing site to another location, and the section is supplied assembled and ready to fit. It is not generally used to refer to electrical or electronic components of a machine, or mechanical parts such as pumps, gearboxes and compressors which are usually supplied as separate items, but to sections of the body of the machine which in the past were fabricated with the whole machine. Prefabricated parts of the body of the machine may be called ‘sub-assemblies’ to distinguish them from the other components.

The most widely used form of prefabrication in building and civil engineering is the use of prefabricated concrete and prefabricated steel sections in structures where a particular part or form is repeated many times. It can be difficult to construct the formwork required to mold concrete components on site, and delivering wet concrete to the site before it starts to set requires precise time management. Pouring concrete sections in a factory brings the advantages of being able to re-use moulds and the concrete can be mixed on the spot without having to be transported to and pumped wet on a congested construction site. Prefabricating steel sections reduces on-site cutting and welding costs as well as the associated hazards.

Pre-engineering is the practice of designing a building and compiling materials to be assembled onsite. It removes the need for a contractor to source materials from multiple suppliers, as the materials will arrive onsite as a package with a plan set explaining assembly, similar to a child’s building block kit. An important difference to note is that the pre-engineered building requires on-site construction.

Benefits of pre-engineered/modular buildings compared to conventional construction

Modular vs. conventional construction:

A modular building is a pre-engineered structure that is flexible enough to satisfy virtually any requirement. It is usually tougher than standard drywall construction as well as its ability to be expanded, relocated, reusable, and recyclable. The primary advantage of modular/pre-engineered buildings over conventional construction is that they can save up to 35% on initial construction costs such as labor and materials.

Applications:

Office buildings, training centers, aircraft structures, schools, hangers, dormitories, dining facilities, temporary office space, restrooms, guard shacks, border stations, restrooms, mezzanines, and much more.

The chart details some benefits of pre-engineered modular buildings:

| Greener | Faster | Smarter |

|---|---|---|

| The factory-controlled process generates less waste, creates fewer site disturbances and allows for tighter construction. | Construction of modular buildings occurs simultaneously with site work, allowing projects to be completed in half the time of traditional construction. | Modular buildings are built with the same materials and to the same building codes and architectural specifications as traditional construction. Once assembled, they are virtually indistinguishable from their site-built counterparts. |

| Less site disturbance On-site traffic is greatly minimized from workers, equipment and suppliers. | Reduced construction schedule Because construction of modular buildings can occur simultaneously with the site and foundation work, projects can be completed 30% to 50% sooner than traditional construction. | Safer construction The indoor construction environment reduces the risks of accidents and related liabilities for workers. |

| Greater flexibility and reuse Modular buildings can be disassembled and the modules relocated or refurbished for new use, reducing the demand for raw materials and minimizing the amount of energy expended to create a building to meet the new need. | Elimination of weather delays 60 - 90% of the construction is completed inside a factory, which mitigates the risk of weather delays. Buildings are occupied sooner, creating a faster return on investment. | Better engineered building and Building Information Modeling PMC relies on advanced BIM for visualization to assess the energy performance and identify the most cost-effective efficiency measures. PMC is ideal for the use of this technology where the construction process is already a collaboration of systems, materials and people—much like the software itself. |

| Less material waste When building in a factory, waste is eliminated by recycling materials, controlling inventory and protecting building materials. | Built to code with quality materials Modular buildings are built to meet or exceed the same building codes and standards as site-built structures, and the same architect-specified materials used in conventionally constructed buildings are used in modular construction projects – wood, concrete and steel. | Limitless design opportunities Modular units may be designed to fit in with external aesthetics of any existing building and modular units, once assembled, are virtually indistinguishable from their site-built counterparts. |

| Improved air quality Because the modular structure is substantially completed in a factory-controlled setting using dry materials, the potential for high levels of moisture being trapped in the new construction is eliminated. |

How to purchase pre-engineered/pre-fabricated buildings from us

After agencies have determined their requirements to include the salient characteristics of the building (see below), they are ready to start the acquisition phase. GSA has a whole host of Pre-fabricated and Pre-engineered buildings available for agencies to purchase through our Multiple Award Schedules Program.

Under Facilities the following Special Item Numbers (SIN) are applicable to pre-engineered and pre-fabricated buildings:

332311P - Includes storage structures made of wood, fiberglass, steel, aluminum, metal, tension fabric, pre-cast concrete, and more. All options include accessories and may contain recycled or bio-based materials.

Installation solutions can be found under the following ancillary SIN:

238910 - Include installation and site preparation services ordered in conjunction with buildings and structures, building materials, storage tanks/systems, services for alternative energy solutions or power distribution equipment, and fuel dispensing and management systems purchased under this schedule contract.

Salient characteristics of a building

Below are some examples of salient characteristics that can be used to assist in determining potential requirements for buildings.

Building code requirements

- International

- Federal

- State

- Local

Building framing

- Material

- Square footage

- Framing

- Bay spacing

- Eaves heights

- Roof pitch

- Sheeting

- Insulation

- Rod bracing

- Wind posts

- Columns

- Roof beams

- Anchor bolt layouts

- Primary and secondary structural components

- Primed structural components, purlins, and girts

- Paint ready material

- Design adaptability

- Regulatory compliance: federal, state, local codes for any location

Roofing and gutter systems:

- Pitch

- Seam

- Roof panels

- Roofing material

- Fall protection for erectors

- Warranty for finish panels

- Warranty includes: all structural components…blistering, peeling, cracking or chipping

- Corrosion protection

- Design adaptability

- Regulatory compliance: federal, state, local codes for any location

Walls, fascia door, lighting, electrical, flooring, HVAC, and windows

- Personnel doors

- Windows

- Vents

- Access panels

- Cargo doors

- Corrosion protection

- Design adaptability

Environmental

- Environmental standards

- Erection drawings

- Certified (drawings)

Service

- Customer service availability / engineering solutions

- On-site technical representative

- Site prep

- Installation (distance of utilities)

Logistics

- Shipment

Ordering procedures

The Federal Acquisition Regulation guides the correct use of the MAS program. Ordering procedures vary based on whether or not a Statement of Work is required. Ordering activities must use the procedures in FAR 8.405-1 when ordering Schedule contract supplies (products) and fixed-price services for a specific task, where a SOW is not required (or example: installation, maintenance, and repair).

For Ordering Procedures for Services Requiring a SOW (or example, when ordering Schedule contract services priced at hourly rates), please refer to FAR 8.405-2.

Frequently asked questions

Are temporary buildings covered under disaster recovery program?

Yes. Any temporary building maybe ordered under the disaster recovery program, depending on the requirements of the customer.

Do pre-engineered and pre-fabricated buildings and structures include electrical wiring and plumbing?

Yes, the buildings and structures include options that make the units fully operating buildings.

Where can I point customers for assistance?

Customers requiring assistance should contact our National Customer Service Center 800-488-3111, ncsccustomer.service@gsa.gov. Ask to speak with your agency customer account POC.

Are any of the prefabs made with sustainable materials? If so, what? If not, is there any future vision in the industry to create sustainable prefabs?

‘Sustainable’ doesn’t have a definite definition. We have some vendors that have buildings made from scrap metal. Ongoing initiative to get sustainable…

Are any of the prefabs LEED certified?

No buildings are LEED certified at this time

Are sidewalks and utilities required to complete a project covered under any ancillary services SINS or categories?

Sidewalks fall under SIN 238910, installation and site preparation requiring construction. Utility hook up is within the scope of SIN 238910; the requirement for utility hook up is determined by the customer.

What services (minor construction, ancillary repair) are included in the procurement of the prefab building?

Any services beyond delivery of the building are not covered under the building SIN. Services must be solicited and quoted under the applicable services SIN. The applicable SIN is determined by the extent of services required to provide a turnkey solution.

What types of services are excluded when hooking up a prefab building to the utilities?

Any non-standard electrical requirement within the building.

What is included in the building itself?

Standard and optional items vary by contract, dependent on the standard and optional items offered by the contractor. Non-contract items may can be included in a procurement as open market items. However, open market items are subject to formal price evaluation procedures.

How do you define “Construction”, “Ancillary Repair & Alteration”, and “Minor Construction?”

Complex construction is not approved under GSA MAS contracts.

Facilities Structures includes commercial products that may require services in conjunction with the purchase of the product.

There are three basic types of services available:

- ANCILLARY SIN Ancillary Service for functions such as set up, simple installation, and training. (Excludes construction and services subject to the Service Contract Act)

- ANCRA SIN Ancillary Repair and Alteration requiring minor construction (includes Davis Bacon and construction clauses)

- SIN 238910 Installation and Site Preparation requiring Construction, which is necessary, to install a Pre-Engineered or Prefabricated Building or Structure, (includes Davis Bacon and Construction Clauses).

Ancillary Repair and Alteration SINs are available in conjunction with purchase of products that require minor construction to be installed properly, such as minor construction necessary to install a door or window, repair drywall, or paint a room. SIN categories are also available to provide installation and site prep requiring construction, services ordered in conjunction with purchase of products to be installed under the Schedule contract—a prefabricated building, solar energy system, roofing, generator, transformer, and more. Davis Bacon and Construction Clauses are incorporated into Facilities Structures contracts offering installation and site preparation requiring construction and R&A. We negotiates fixed rates for services (rates include consideration of prevailing Davis Bacon wage rates). The applicable Davis Bacon wage determination is incorporated at the task order level, when place of performance has been determined.

Does the schedule include furniture, bathroom fixtures, and kitchenettes?

Contracts usually do not include furniture. However, it is routine to include optional bathroom fixtures or kitchenettes depending on the building and contractor. A teaming arrangement may be necessary to furnish the building or structure.

What preconditions are required at the proposed site? This would include water and sewer lines, electric and gas connections, and more.

These utilities must be available at the site.

If extensive site preparation is required, is this covered under the schedule?

Site prep is covered under the installation and site preparation SINs, which cover specific products categories:

- SIN 238910 Site preparation is limited to the immediate location of the installation, such as leveling and clearing ground, pouring a cement pad, etc.

Is the foundation part of the schedule?

Yes, a foundation is included under installation and site preparation requiring construction SIN 238910.

Since foundations are necessary, is this considered ancillary?

A foundation is considered under installation and site preparation.

Are there limits on site preparation costs?

No, any cost/price decision is determined by the customer. GSA MAS contracts do not include a limitation at the contract or order level.

Are there options for leasing?

Yes, SIN 532490P Lease/Rental of Pre-Engineered/Prefabricated Buildings and Structures. This includes portable/mobile office buildings, restroom facilities, and temporary living quarters such as mobile homes and tension fabric structures. The lease or rental of these portable structures are suitable for emergencies and disaster recovery efforts.

Points of contact

Kyle Finegan, contracting officer

kyle.finegan@gsa.gov

817-850-8233

Mataya Jordan, section chief

mataya.jordan@gsa.gov

817-850-8161

Ahisha Alexander, branch chief

ahisha.alexander@gsa.gov

817-850-8358

Sample statement of objectives and statement of work

When writing a Statement of Objective or Statement of Work, when possible state the purpose, rather than the specific detail. This will allow the contractor to propose based on the materials they would use, rather than the materials necessary to complete the project. This can result in lower pricing. If a specific detail is required, then list.

Statement of objectives

Title: Secure Temporary Office Modular Project

1.0 Purpose. This Statement of Objectives describes the basic objectives for the completion of a Secure Temporary Office Modular Project. The Statement of Objectives is provided in lieu of a Government written Statement of Work. This approach provides potential offerors the flexibility to develop cost effective solutions and the opportunity to assess the offeror’s understanding of all aspects of the effort to be performed by eliminating the “how to” instructions to accomplish the required effort normally contained on the SOW the government provides to prospective offerors. Teaming (teaming arrangement) with other schedule holders may be necessary to complete your proposal.

2.0 Period and Place of Performance. 150 days. Hill Air Force Base, Utah

3.0 Background. The STOMP must have the following attributes

- Minimum of 32,600 SQFT to house approximately 300 staff and required equipment. (Attached floor plan solution utilizes 46 trailers at 11’-10” x 60’) 252 work stations (cubicles)

- 11 private Supervisors Offices

- 3 Planning (Conference) Rooms

- 2 Men’s multi-stall restrooms

- 2 Women’s multi stall restrooms

- Lobby with Security Checkpoint desk

- Entry Vestibule

- 1 Men’s and 1 Women’s Lobby Restroom

- 1 Break Area/Kitchen

- 1 Communications Room

- 1 private MCCR (Communications Manager) Office

- 1 Receiving Bay with Rollup Door

- 1 janitor’s closet

- 4 storage closets (1 in lobby)

- 1 Mechanical Room

- 1 Electrical Room

Specifications

Basis of proposal: Proposal is based on the statement of objectives and drawings reflected herein. It is the intent of these documents to outline the requirements for a temporary modular office complex to be factory manufactured off-site and delivered to a specified location. The contractor is also responsible to prepare the site and connect the utilities to the temporary facility.

Transportation permits: Transportation permits are the responsibility of the contractor.

Performance and Payment bonds: Performance and/or Payment bonds are required.

Insurance: Standard general liability and builder’s risk coverage until work is complete.

Wage rates: Davis Bacon and prevailing wage rates and certified payroll excluded for manufacture, delivery and incidental work relating to installation. Davis Bacon and prevailing wage rates and certified payroll applies to only non-incidental work performed on site.

Inspection approvals: Standard base inspection protocol will be utilized.

Close-out documents: Standard Operating & Maintenance manuals including warranty information provided at the completion of the project.

Codes, Design Criteria: 2009 IBC/UFC/ADA/NEC/IPC/IMC/IECC. Buildings will be constructed to meet or exceed standards as defined in 2009 IBC Occupancy Group B, and Type V-B construction, sprinkled per UFC 3-600-1. The buildings are built in compliance with UT state modular program. The Trailer Facilities are within allowable story and floor limits for Occupancy and Type. The Trailer Facility buildings are not subject to progressive collapse requirements (less than 3 stories). The Trailer Facility structures are not subject to ATFP requirements due to both the nature of the structures (relocatable building) and duration of intended use (5 years or less) UFC 4-010-01.

Design criteria: Wind - 90 mph wind exposure c; sprinkled; seismic as required for HAFB, Utah; 50 psf floor load; 40 psf roof load.

Architectural/Engineering: Contractor must employ the services of engineering professionals as necessary to meet design criteria and meet applicable codes.

Frame: Perimeter type steel c-channel, sized to meet design criteria.

Transportation rigging: Removed and returned to mfg.

Floor Insulation: R-30 no moisture barrier

Joists: Sized and spaced to meet design criteria

Floor Decking: Minimum ¾” T&G

Underfloor board: 5/8” Plywood on underside of floor joists 3

Floor cover #1: Commercial carpet tiles all common staff areas, supervisor offices, MCCR, conference rooms.

Floor cover #2: 1/8” Armstrong 12”x12” VCT floor tiles in bathrooms, lobby, Comm, kitchen, break area, janitors closets, Mech room, Elec room, storage closets, and hallways.

Floor cover #3: Recycled Tire Tread entrance flooring in Entry Vestibule. Also provide a 6’x6’ area at the Side Lobby entrance.

Base molding #1: 4” continuous vinyl cove base- throughout building.

Exterior Walls: 2” x 6” wood studs spaced to meet design criteria. 5/8” Exterior Plywood Sheathing, 5/8” Interior Sheetrock, R-21 insulation.

Siding: 29 gauge ¾” HI Rib Metal

Exterior trim: To match siding.

Perimeter Skirting: Siding/framing to match exterior finish with chain-link security barrier buried to 12” depth below grade.

Interior Walls: 2x4 framing spaced to meet design criteria, ½” Sheetrock, R-13 sound batts except around Lobby and RCV Bay, where sheetrock is 5/8” both sides.

Support Walls: Utilize mid-span walls/columns in each trailer module to lighten roof beams/trusses.

Interior finish #1: Tape, texture to level 4 finish and paint in all areas except as noted.

Interior finish #2: Fiberglass reinforced panel (frp) - full height over 5/8” substrate on wet walls in restrooms, janitor’s closet.

Beams, Rafters, joists: Sized and spaced to meet design criteria.

Ceiling: 2’ x 2’ suspended acoustic with square edge.

Ceiling height: nominal 9’

Ceiling Insulation: R-38

Roof Sheathing: 5/8” plywood

Roof Joist Underside: 5/8” Sheetrock

Roofing: 60 mil epdm, 20 yr material warranty

Roof slope: 1/8 in 12

Rain Gutters: Mini over Doors

Emergency Exit: Double 3’-0” x 6’-8” 18 gallon painted reinforced metal door w/ 16 gallon HM with center stile between doors.

- Doors must be secured with emergency egress hardware on the inside. No exterior hardware. Egress hardware must incorporate an integral Audible alarm which activates upon opening.

- Doors must be equipped with an automatic, non-hold door-closer which must be installed internal to the Facility.

- Hinges must incorporate non-removal hinge pins.

Interior Lockable Doors (Offices, Planning, MCCR, Storage, Janitor, Comm): 3’-0” x 6’-8” Solid Core Prefinished Wood w/ Alum Frame.

- Provide with lockable lever hardware with removable cores.

- Offices, MCCR, Comm, Planning rooms to have glazing kits.

Interior Public Doors (Restrooms, Break room, Hallways): 3’-0” x 6’-8” single or double (as shown) Solid Core Prefinished Wood w/ Alum Frame.

- Hardware to be Push-Pull with closers.

- Hallway and Break room doors to have glazing kits.

Outer Vestibule Entry Doors: Double 3’-0” x 6’-8” aluminum store front, mill bronze.

- Pull handles on exterior. Push handles in interior.

- Removable-core lock w/ integral simultaneous top/bottom latch on active leaf.

- Hinges must incorporate non-removable hinge pins.

Inner Vestibule Access Doors: Double 3’-0” x 6’-8” 18 gallon painted reinforced metal door w/ full lite, 16 gallon HM frame with center stile between doors.

- Doors must be equipped with an automatic, non-hold door-closer which must be installed internal to the Facility.

- Exit Door must be equipped with emergency egress hardware on the inside.

- Entry Door must have a removable-core lockable lever handle on the Lobby side. Secured side hardware must be a passage lever.

- Hinges must incorporate non-removable hinge pins.

- Entry door must be provided with electric strike and installed so as to accommodate Vindicator access.

Lobby Side Door: 3’-0” x 6’-8” 18 gallon painted reinforced metal door w/ 16 gallon HM frame as configured on drawing.

- Door must be equipped with an automatic, non-hold door-closer which must be installed internal to the Facility.

- Door must be equipped with emergency egress hardware on the inside.

- Door must have a pull handle on the exterior of the door with a high security keyway for use in the event of an access control system failure.

- Hinges must utilize non-removable hinge pins.

- Door must have glazing kit.

Secure Access Doors (Lobby into Controlled Space): Separate 3’-0” x 6’-8” 18 gallon painted reinforced metal door w/ 16 gallon HM frame configured as per drawing. One door is entrance to secure space. Other door is exit from secure space.

- Doors must be equipped with an automatic, non-hold door-closer which must be installed on the secured side.

- The exit door must be equipped with emergency egress hardware on the secure side. No hardware on the lobby side.

- Entrance door must have a removable-core lockable latch handle installed on the lobby side of the door and a passage latch handle installed on the secure side.

- Hinges must utilize non-removable hinge pins.

- Both doors must have glazing kits.

Rollup Door: 8’x 7’ Insulated Rolling Door, 18 gallon minimum.

- Secure interior slide latches (both sides of door)

Equipment Room Doors: 3’-0” x 6’-8” 18 gallon painted reinforced metal door w/ 16 gallon HM frame configured as per drawing.

- Provide with lockable knob hardware with removable cores.

Glazing Kit: 6”x27” Reinforced Vision Kit where specified above.

Windows: 3’-0” x 4’-0” Fixed.

Glazing: Clear, dual glazed, low-e

Blinds: I” metal at each exterior window

Window Security: Windows must be protected by permanently affixed reinforced steel bars.

- Bars must be a minimum of 1/2 inch diameter steel, welded vertically and horizontally six inches on center. The bars must be welded at intersections.

- The bars must be secured to a frame. This frame must be permanently anchored to the secure-side wall with six inch anchors. Anchors must be non-removable.

Electrical Service: Provide three phase 480/277 volt service for HVAC Units and Lighting. Transform down to 208/120 volt for all other loads.

Panels: Provide and install interior sub panels and transformers, sized per design criteria and code. Provide and install MDP as or if required. Connect sub panels to MDP or disconnects on site as required.

Main Building panel: Provide and install exterior/interior mounted main distribution panel for a single point of connection ready for final utility connection.

Service connections: Provide and install conduit and wire to connect sub panels to MDP.

Ground: Provide and install service ground rod at each MDP.

Transformers - regulators: Provide, install and connect all necessary transformers.

Circuit wiring: Per code #12 awg wire or greater

Conduit: EMT, MC cable

Interior lights: 2’ x 4’ fluorescent 3 bulbs recessed, t-8 electronic ballasts, prismatic. All conference rooms to have dimmers for fluorescent lights.

Exterior lights: General purpose exterior lighting providing 360-degree facility coverage

Exit signs: As required by code

Emergency lights: 2’ x 4’ fluorescent 4 bulb, recessed, t-8 electronic ballasts, prismatic diffusers with battery back-up, per code

Receptacles: 20 amp 125 VAC two pole 3 wire installed as per code. Also install 15 receptacles at office equipment to be locations designated by bldg. user (at drawing review stage).

Dedicated receptacles or circuits: Dedicated wired j-box in ceiling above fire alarm panel location prep for installed fire alarm system. Provide dedicated wired j-boxes in ceiling for cubicle power interconnection at a rate of two workstations per circuit.

Office Furniture: Contractor to provide and install 152 cubicle workstations and security desk workstation as per attached floor plan. Private offices and remaining workstation locations must be roughed for data and electrical (i.e. conduits/cables/fiber) such that each location is ready for future furniture installation.

Break Room Appliances:

Exterior Outlets: Install outlets at exterior perimeter at the following locations:

- Near rollup door

- Near front entrance

- Adjacent to each HVAC unit

Voice and data: Provide and install boxes at 15 designated office equipment (printer, etc.) locations with home run capability (via conduits and/or cable trays) to Data/Comm Room.

Provide and install j-boxes above ceiling at all cubicle locations for interconnection to cubicle workstations. Each cubicle requires capacity for 8 cables (either copper or fiber).

Provide home run capability (via conduits and/or cable trays) to Data/Comm Room.

Provide and install j-boxes in wall at all supervisor offices. Each cubicle requires capacity for 8 cables (either copper or fiber) divided among 3 separate boxes/conduits on each of 2 designated walls in each office.

Provide home run capability (via conduits and/or cable trays) to Data/Comm Room.

Provide, install and interconnect cable trays and conduits above ceiling between modular units.

Fire Alarm: Provide and install fire protection flow switch and other alarm devices as required by applicable codes.

Fire Alarm Connection: Provide devices (Monaco transmitter) to communicate fire alarm signals with Fire Department. Provide all interconnecting conduit and wiring within the building for a complete, working system.

Fire sprinkler system: Provide and install wet pipe fire sprinkler system to include riser and shut off valves within the building.

Fire sprinkler system - interconnection: Provide labor and materials to connect fire sprinkler system together to a single connection point below the floor (within the crawlspace under the fire sprinkler closet). Design must be based on adequate water pressure being provided by customer. Testing included.

*Site Utilities: in the final purchase package, a site map will be included which indicates existing utility locations, distances, and conditions.

Fire sprinkler system connection: Professionally size and connect building fire sprinkler riser to site water source as indicated on Site Plan. Include backflow preventer, post indicator valve, two fire hydrants, pumps, etc. as required.

Gas Connection: Professionally size and connect all gas-fired HVAC Units to underground gas main at location indicated on site plan.

Electrical Utility Connection: Bring electrical from power source to single point electrical connection (480/277 Volt) at building. This will include the necessity of a step-down transformer from the existing overhead service. Contractor to make final connection to site power source. Refer to site plan.

Comm/Data Utility Connections: Run 2 each 4” Conduits from Communications Room underground to a location 5’ east of the Modular Complex. Cap buried underground ends. Insert pull strings in both conduits.

Potable Water Connection: Professionally size and connect building water system to appropriate underground water main as indicated on site plan. Include meters, pressure regulators, backflow preventers, etc.

Site preparation: Prepare site by grading and excavating for the foundation, utilities and new parking. Compact as required per design. Prepare SWPPP and grade site accordingly.

Below grade concrete: Labor and materials to provide engineered below grade reinforced concrete footings. Bottom of footings to be below frost line (30”).

Site Concrete: Provide and install concrete steps, ramps, sidewalks, curbs, gutters, utility pads per site drawing and ADA requirements. As a minimum, site concrete work should include the following

- Concrete stairs and landing at main entrance.

- 3’ x 8’ Concrete dock at Rolling Door

- Concrete handicap ramp at main entrance

- Concrete sidewalk/walkway from proposed parking lot area to main entry steps/ramp.

Emergency exit stairs: Provide metal (Galvanized steel or aluminum) landing and stairs with handrails at all emergency exit locations and at side Lobby Door and Equipment room door. Landings to be 5’x7’. Utilize open stair tread material for stairs/landing.

Fire extinguishers: As required by code

Water lines: PEX / copper

Shutoff valves: Chrome all fixtures: Chrome all fixtures

Exterior faucets: Frost proof with plumbers key

Water line interconnections: Make crossover connections (hot and cold water lines) at modular mainlines, as or if required

Waste lines: PVC schedule 40 drains & vent, individual stubs to crawl space

Sewer manifold: Provide labor and materials as necessary to manifold individual sewer stubs together to a single point of connection within crawl space (including clean-outs per code).

Water coolers: Two (2) dual height, ADA compliant, electric in areas designated by customer

Water heaters: Multiple electric on-demand sized appropriate for use requirements and conditions.

Janitors sink: Floor mounted commercial grade, includes faucet and dual handles. Brackets and shelving to hold housekeeping items.

Toilets: Floor mounted, flush valve, elongated bowl, vitreous china, ADA compliant

Urinals: Wall hung vitreous china with flush valve

ADA grab bars: Brushed, stainless steel, per code

Rest room accessories: Dual roll toilet paper holder at each toilet. Paper towel, dispensers, mirrors.

Toilet partitions: Baked Enamel

HVAC: Wall mount Gas/Electric HVAC Package Unit. Natural gas heat, 3 phase electric. Quantity and sized to be determined by Mechanical designer. In addition to the calculated building loads, 10 tons of cooling should be allotted to the Communications Room. All HVAC units to be interconnected to single HVAC emergency shutoff located at security desk.

HVAC Security: Vents or duct openings that penetrate the perimeter of the Facility and exceed 96 square inches must be protected with permanently affixed bars or grills.

- If bars are used, they must be a minimum of 1/2 inch diameter steel, welded vertically and horizontally six inches on center. The bars must be welded at intersections. The bars must be secured to a frame. This frame must be anchored to the secure-side wall with six inch anchors.

- If grills are used, they must be of ¾ inch-mesh, #9 (10 gauge), case-hardened, expanded metal.

- If bars or grill are required, an access port must be installed inside the secure perimeter of the Secure Facility to allow visual inspection of the bars or grill.

Supply ducts: Galvanized with exterior insulation

Registers: 24” x 24” adjustable manufacturer’s std

Return air: 24” x 24” adjustable manufacturer’s std

Thermostats: 7 day programmable with occupant override variable, include locking covers over thermostats.

Test and balance: Certified test and balance

Bath exhaust: Switched fans, sized per code.

Counter tops: Solid surface w/ integral sinks

Backsplash: Ceramic tile backsplash or equal

Cabinets: Base and overheads, with solid hardwood fronts

Shelving: Melamine covered, at storage closets

Cleaning: Clean entire building, remove all labels, vacuum floor, strip, 2 coats sealer and 3 coats wax on all VCT.

4.0 Performance Objectives. The purpose of this statement of objectives is to obtain a contractor to support the Temporary Modular Trailer Facility. Under this effort the contractor is responsible for providing all personnel, supplies, and logistics for the completion of this project. The contractor performs the required work in accordance with all industry standards and regulations.

4.2 Subcontractor Expenditures Plan - Deliverable. The Contractor must prepare and deliver a Subcontract Expenditures Report that discloses actual subcontract expenditures by company name, business size standard (i.e., Woman Owned Business, Veteran Owned Business, etc.), and other socioeconomic programs (i.e., Indian Incentive Program, Historically Black Colleges and Universities and Minority Institutions, etc.). See FAR Part 19.

4.3 Quality Assurance Surveillance Plan (QASP). The Conductor must establish a complete Quality Control Program (QC P) to assure the requirements of the contract are provided as specified. The QCP must be an identifying issue in the quality of services before the level of performance is unacceptable, and should be contained within a formal written Quality Assurance Surveillance Plan which must be submitted with the vendor final proposal. The program and document must be subject to the approval of the Contracting Officer (CO) and the Contracting Officer’s Technical Representative(COTR).

4.4 Applicable Information. Contractor is responsible for providing:

- Recommendations for industry proven cost cutting methods, and improved performance measures under the contract.

- Effectively ensuring quality control.

- Ensure that all contractor and subcontractor personnel proposed to work on the premises under this contract are US Citizens or Naturalized Citizens and must be eligible to work on premises. Failure to comply with these requirements may result in termination of this contract or removal of some contractor’s employees form facilities.

4.5 Constraints. Contractor must work normal hours of 8 am to 4:30 pm Monday thru Friday. Work outside these hours must be approved in advance. Contractor must notify the Contracting Officer of any utility interruption 48 hours in advance. Normal operations of the campus must be kept in operation while the construction is being performed. The contractor must supply any temporary equipment or work needed to keep operations functioning with respect to utility interruptions. Roads and parking areas must be kept operational except for short durations and then only one lane closure is acceptable. Any damage to the Govt is the responsibility of the contractor to repair including the grounds, roadways, curbs and sidewalks. Contractor must comply with base safety and construction policies and with all state and federal safety requirements.

Statement of work

Statement of Work – Modular Office Space 1

1 – Scope of Contract

Provide and set-up a 24’ x 60’modular office. Set-up must include blocking, leveling, seismic anchors and skirting. The contractor must provide a permanent accessible entrance ramp and landing meeting ABA Accessibility Standards: https://www.access-board.gov/aba/ . Offerers must submit with their proposal, a floor plan and complete specifications on materials and construction details to demonstrate the ability to meet the requirements herein. As an option the contractor must install utility lines from the existing office trailer to the new modular office location including power, water, sewer, phone and data (conduit only for data and phone). Connect power, water and sewer as shown on the drawings and specified herein. As an option the contractor must unhook all utilities from the existing office trailer leaving the stub outs in place and demolish the existing office trailer.

List of Attachments:

- Vicinity Map

- Almanor District Site Plan

1.1 – Project Location:

The site is located at 900 Highway 36 in Chester, CA. The contractor must confirm the acceptability of the route to the pad.

1.2 – Government Furnished Property

Government Furnished & Contractor Installed: None

Government Furnished and Government Installed:

- Data/Telecom network equipment and main lines from the existing Fire Trailer

- Refrigerator

1.3 – Contractor Furnished Property and Submittals

The Contractor must furnish all labor, materials (except as listed in paragraph 1.2), equipment, supervision, and transportation necessary for the successful completion of the work described in this contract. A complete set of drawings, stamped by a California licensed engineer and specifications for products to be incorporated in the modular unit must be submitted for approval 30 days prior to beginning production. Drawings must include plan, elevation and detail views of the building, foundation, anchoring and skirting sufficient to determine conformance to the contract. Plans must also include electrical load calculations so the government can ensure Pacific Gas and Electric (PG&E) has sufficient power to the meter.

1.4 – Utilities(Option B)

Contractor must be responsible for locating and protecting above and below ground utilities in the project area. At the site for the new office there used to be a residence which had water, sewer, power and LPG lines. All these utilities have been abandoned but may still be in place. The power line was an overhead line and is indicated on the site plan. See site plan for location of existing utility tie-in points.

1.4.1 - Power

Disconnect the underground conductors that feed the existing office trailer from the box on the west side of the building or from the control panel?. Provide a new PG&E approved service entrance panel on the modular office exterior wall at the location shown on the site plan. Install underground 3” PVC conduit from under the existing abandoned office trailer to the new modular service entrance panel. Conduit must be buried at code depth with properly compacted bedding and backfill material. Where the trench is under asphalt, backfill the top 9” with 6” of compacted ¾” minus crushed aggregate and 3” of ½” minus asphalt. In all other locations, the top 6” of the trench must be compacted ¾” minus crushed aggregate. Run proper sized conductors from the meter pedestal to the new service entrance panel.

1.4.2 - Water

Install underground water line conduit from under the existing abandoned office trailer to the new modular service entrance panel. Conduit must be buried at code depth with properly compacted bedding and backfill material. Where the trench is under asphalt, backfill the top 9” with 6” of compacted ¾” minus crushed aggregate and 3” of ½” minus asphalt. In all other locations, the top 6” of the trench must be compacted ¾” minus crushed aggregate. Tie into existing 1-inch PVC waterline at existing service modular office. Install a new NIBCO4660-S ball valve that is reachable through a Hallmann Sales, LLC GP-100 10”x10” access door installed in the skirting. Insulate all piping with self-sealing closed cell foam tubing

1.4.3 - Sewer

Install underground sewer line conduit from under the existing abandoned office trailer to the new modular service entrance panel. Maintain a minimum of 1% slope in the new sewer line from the new modular office to the existing sewer connection under the existing abandoned office trailer. Conduit must be buried at code depth with properly compacted bedding and backfill material. Where the trench is under asphalt, backfill the top 9” with 6” of compacted ¾” minus crushed aggregate and 3” of ½” minus asphalt. In all other locations, the top 6” of the trench must be compacted ¾” minus crushed aggregate. Tie into existing sewer line to service the modular office. Modify and extend underground line as necessary to provide a new accessible cleanout in a plastic valve box labeled “SEWER”.

1.4.4 – Data/Telecom

Protect existing conduit that stubs up under the existing mobile office trailer for reuse by the government.

1.5 - Use of Utilities

Contractor may use electric, water and sanitary facilities at the project area.

1.6 – Protection of Existing improvements

Pavement, buildings, landscaping and other improvements must be protected by the Contractor. The Contractor must be responsible for repairing any damage to improvements.

1.7 – Office Trailer Demolition(Option A) Statement of Work – Modular Office Space 3

The existing office trailer must be removed and disposed of off the existing government property. Work includes utility disconnection, removal and disposal of office trailer.

- Regulatory Requirements: Comply with governing EPA notification regulations before beginning demolition. Comply with hauling and disposal regulations of authorities having jurisdiction.

- Hazardous Materials: It is not expected that hazardous materials will be encountered in the Work.

- The Government before start of the Work will remove hazardous materials.

- If materials suspected of containing hazardous materials are encountered, do not disturb; immediately notify the CO. The Government under a separate contract will remove hazardous materials.

- Existing Utilities: Locate, identify, disconnect, and seal or cap off indicated utilities serving buildings and structures to be demolished.

- Arrange to shut off indicated utilities with utility companies.

- If utility services are required to be removed, relocated, or abandoned, before proceeding with building demolition provide temporary utilities that bypass buildings and structures to be demolished and that maintain continuity of service to other buildings and structures.

- Cut off pipe or conduit a minimum of 24 inches (610 mm) below grade. Cap, valve, or plug and seal remaining portion of pipe or conduit after bypassing. Leave a t-post or lath at each utility location with a label indicating each utility so they can be located when performing the utility work for the new modular office.

1.8 – Modular Office Pad

The government will provide a site that is relatively level and capable of a minimum 1500 psf bearing capacity.

1.9 – Modular Office Unit

Bathroom dimensions must be adjusted as necessary to meet accessibility standards. Below are the minimum requirements that must be met:

General:

- Unit must be fully accessible and meet the International Building Code. Unit must be designed and installed to meet the snow, wind and seismic forces for the location.

- Office area must consist of four private offices with the balance of space being open office area for maximum flexibility.

- Provide accessible entry door(s) as required by code with photocell metal halide security lights. Entry door(s) must be ANSI/SDI-100, Grade III, extra heavy-duty, Model 2 + 2A, with minimum 16-gauge galvanized steel faces. Frame(s) must be 16-gauge galvanized steel with one piece welded construction.

- Minimum R-19 wall, R-38 roof and R-11 floor insulation or meet latest California code requirement, whichever is greater.

- Roof must be gable style with minimum 12 inch eaves and rakes. Provide minimum 30 year standing seam roof. Color must be selected by the Contracting Officer from the manufacturers standard color selections.

- Exterior siding and skirting must be LP Architectural Collection 16 inch Double 8” Bold Profile or approved equal. Skirting must be secured to the ground with 2” x 4” pressure treated wood rated for ground contact. Remaining framing to support skirting must be 2” x 4” @ 16” OC and installed straight with no visible waviness in the finished skirting. Use matching LP SmartSide trim and fascia for building and skirting and LP SmartSide Soffit for the eave and rake enclosures.

- Provide minimum ½” drywall interior with manufacturer’s standard finish. Color must be selected by the Contracting Officer from the manufacturers standard color selections.

- Ceiling must be heavy duty Armstrong 15/16” T-grid with Armstrong #1733, 2’ x 4’ x 5/8” acoustical lay-in tiles or approved equal. Any damaged components from shipping to the site must be replaced with new.

- Interior doors must be NWWDA I.S.1-A solid core or better with factory finish. Color must be selected by the Contracting Officer from the manufacturers standard color selections.

- All door hardware must be heavy duty commercial grade with satin chrome finish. Entrance lockset must be Schlage ND53PD RHO 626 or approved equal. Office locksets must be AL50PD SAT 626 or approved equal. Exterior door(s) must have continuous weather seals and keyed alike locks. Private offices must have locks keyed separately that will also unlock entrance door(s).

- Windows must be Milgard Style Line Horizontal Sliders with Suncoat Low-E glass or approved equal. Minimum size must be 4’0” x 3’6”.

- Wall to wall carpet throughout office areas must be minimum 26 oz. commercial grade loop pile. Install by direct glue down method. Color must be selected by the Contracting Officer from the manufacturers standard color selections.

- Exterior siding and trim colors must be selected by the Contracting Officer from the manufacturers standard color selections. Paint must be Kelly Moore, Benjamin Moore, Sherwin Williams acrylic latex or approved equal.

Bathrooms:

- One Men’s and one Women’s fully accessible bathroom in compliance with the ABA Accessibility Standards.

- One commercial duty toilet or approved equal per bathroom.

- One vitreous china sink, 304 SS framed mirror, GFCI outlet, 304 SS double roll toilet paper holder and 304 SS tri-fold paper towel dispenser per bathroom.

- Ventilation fan in each bathroom that comes on with the light and has adjustable off delay.

- Commercial 0.080” sheet vinyl flooring. Color must be selected by the Contracting Officer from the manufacturers standard color selections.

Kitchenette: (Option C)

- Base cabinet length must be 5 feet to include a 30” sink base with double doors and 30” base with two drawers and double doors. Leave room for a 36” government furnished refrigerator between the cabinet and the wall.

- Matching wall cabinet length must be 5 feet to include two 30” wide by 42” tall double door cabinets.

- Matte finish one piece laminate countertop with bull nose drip edge and integral backsplash.

- Single bowl stainless steel sink with soap tray, Elkay Model ECC2522 or approved equal.

- Moen Model 7425BC Chateau single lever faucet or approved equal.

- Cabinets must be Armstrong Allwood in Branford style or approved equal. Wood finish to match interior doors.

- All doors and drawers must have brushed stainless steel wire pull handles.

- Mounted 5 pound Type A-B-C fire extinguisher in semi-recessed wall cabinet.

HVAC and Plumbing:

- Instantaneous electric water heaters mounted under all sinks.

- Ducted high efficiency HVAC system using external wall mounted high efficiency heat pumps with economizers and auxiliary electric heat. No jump ducts allowed.

- Ducted bathroom exhaust fans per code requirements.

- 7-day programmable thermostat with battery backup.

- All copper or Pex waterlines. Insulate all piping with self-sealing closed cell foam tubing.

- Provide a cleanout for the trunk lines under the modular and extend to the skirting with a stainless steel Watts CO-480-RD cover or approved equal.

Electrical/Communications:

- Provide T-8 2’ x 4’ lay-in fluorescent lighting with prismatic diffusers and electronic ballasts throughout. Lighting levels must be appropriate for office occupancy.

- Provide a minimum of 20 duplex wall outlets and 4 duplex floor outlets. Floor outlets must be placed in the open space a minimum of 8 feet from any wall. All duplex outlets in office areas must be 20A and spaced as needed to meet code.

- Provide a 2 port data outlet (phone and data) adjacent to each duplex electrical outlet with a ¾” conduit and pull string run in the wall to above the suspended ceiling.

1.10 – Final Testing

Upon completion, the building and utility systems must be tested in the presence of the COR to ensure all components and systems are functioning properly. Provide the COR with a 3 business day advanced notice. If installation of the utilities option is not performed contractor must perform utility testing with a generator for the power and must pressurize the water system using potable water from a portable water tank. During the sewer system testing use only potable water and use only enough water to ensure the system is working correctly. The water from the sewer system test may run onto the ground.

2 – Time for Completion

All work (including final clean-up) must be completed within 60 calendar days from the issuance of the Notice to Proceed.

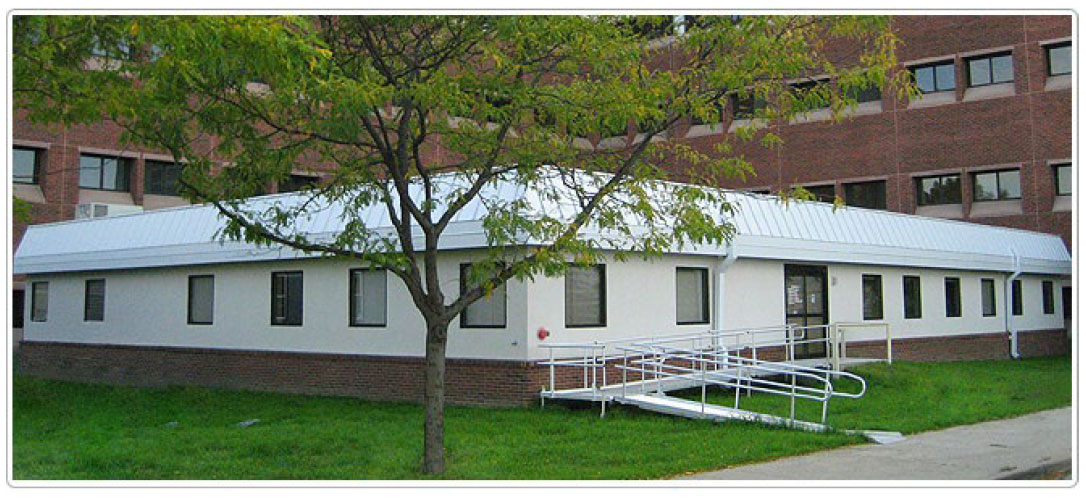

Appendix A: sample modular / pre-engineered photos

U.S. General Services Administration

U.S. General Services Administration